Introduction

Welcome to this comprehensive guide, your roadmap to DAS-Cloud's specialized dashboard pages designed to optimize machine observability and monitor performance across various scopes.

This article covers the following dashboard pages and their included metrics:

- Home Page: A real-time monitoring hub for all machines within the warehouse.

- Machine Specific View: Detailed insights into individual machine metrics and configurations.

- Warehouse Summary: A comprehensive overview of warehouse performance metrics.

- Alarm Analytics: An analytical approach to machine alarms and fault patterns.

- Shift Metrics: Evaluation of shift productivity and Overall Equipment Effectiveness (OEE).

- Data Forecasting: Predictive insights into future operational trends.

- Maintenance Planner: A proactive tool for monitoring and scheduling machine maintenance.

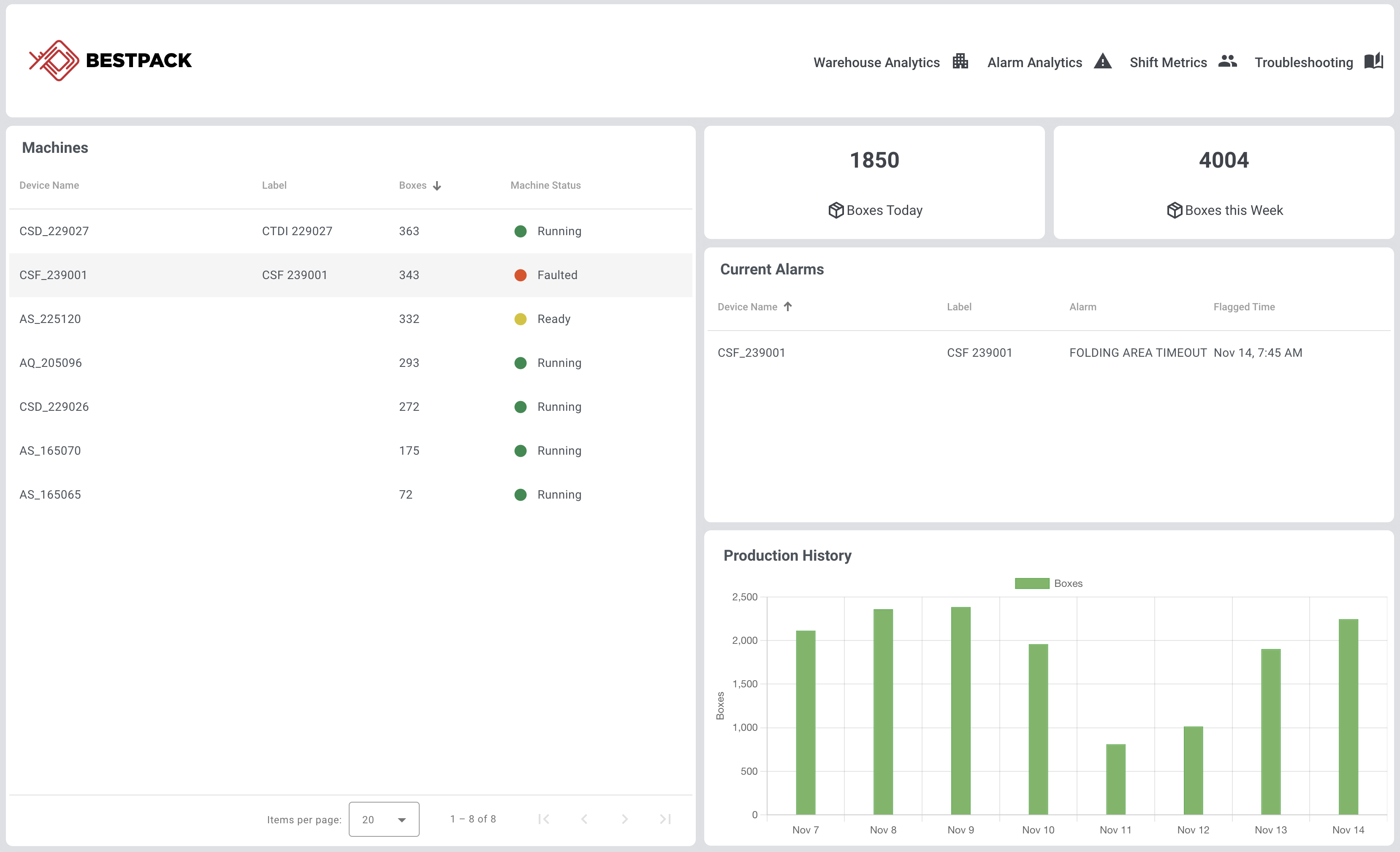

Home Page

This page is designed to be used to monitor the real-time status of all machines at the warehouse. It will update in real-time and includes data for the current day/week.

1) Navigation Bar

Use this bar to navigate between different dashboard pages by clicking on the icons.

2) Machines List

A list of all machines equipped with an active DAS-Cloud subscription. Clicking on a machine name will redirect you to the Machine Specific Page, where you will find a dedicated page for detailed insights.

-

Label: Customizable name assigned to each machine. To modify a machine's label, refer to the Machine Info Placard located on the Machine Specific Page

-

Boxes: Displays the number of boxes sealed by each machine on the current day.

-

Machine Status: Real-time status of each machine

- Offline: Machine is powered off or not connected to the internet.

- Ready: Machine is online and ready to initiate operations.

- Running: Machine is actively sealing boxes.

- Faulted: Machine has encountered an issue and is currently stopped

3) Quick Access Tiles

-

Boxes Today: The total number of boxes sealed by all machines as of today.

-

Boxes this Week: The cumulative count of boxes sealed from Sunday 12 AM to Saturday 11:59 PM of the current week.

4) Current Alarms

A list of any machine that is currently faulted. Includes the current fault name and the local time it was flagged.

5) Production History

A chart showing the total number of boxes that have been taped per day for the last 7 days.

Machine-Specific Page

1) Navigation Bar

Switch between various preset time frames using the center buttons or fine-tune your view by selecting specific dates using the date range selector.

2) Machine Info Placard

-

Machine Identifier: Specifies the machine's family type and unique serial number

-

Label: A customizable label for the machine

-

Status: Real-time status of the machine

- Offline: Machine is powered off or not connected to the internet.

- Ready: Machine is online and ready to initiate operations.

- Running: Machine is actively sealing boxes.

- Faulted: Machine has encountered an issue and is currently stopped

-

Monitoring Mode: Indicates the active tape monitoring mode currently selected on the machine

Additional Info

- Lifetime Boxes - The total number of boxes that have passed through this machine since it was built

- Top Tapehead - The total amount of tape this tape head has dispensed

- Bottom Tapehead - The total amount of tape this tape head has dispensed

Additional Info (If Available)

- WiFi Signal Strength - A percentage representing WiFi connection strength

- Data Accuracy - A percentage of how accurate the data provided by the dashboard is. Any value lower than 95% should be concerning.

- HMI Version - Software Version of the HMI

- PLC Version - Software Version of the PLC

Changing Machine Label

Clicking on the pencil icon in the machine info placard will allow you to assign a custom label to the machine. The graphs displayed on the dashboard will automatically utilize your new label.

3) Quick Access Tiles

Boxes - The number of boxes taped by the machine for the selected time window (use the pre-set time window buttons to change the selected window)

Avg Speed - The average cartons per minute speed of the machine

Alarms - Number of alarms for the given time window

Avg Response Time - Average time it took for a user to clear an alarm on the machine

-

Boxes: The total number of boxes taped by this machine for the selected time window

-

Avg Speed: The average speed of the machine measured in boxes per minute

-

Alarms: The total number of alarms flagged by this machine during the selected time window

-

Avg Response Time: The average time it took to clear an alarm on this machine

4) Production Volume

This chart shows the total number of boxes and total tape used for the selected time window. Note for A-series machines, disabling tape monitoring will also disable tape tracking.

5) Machine Utilization

A chart displaying the percentage of time the machines were in the following states:

-

-

Idling: Machine is powered on but not actively sealing boxes

-

Active: Machine is actively sealing boxes

-

Faulted: Machine was in the faulted state and stopped

-

6) Overall Equipment Effectiveness (OEE) Chart

This chart displays machine performance based on Overall Equipment Effectiveness (OEE). OEE is calculated based on three key metrics:

-

Availability: Assesses the machine's utilization rate, calculated as Machine Runtime divided by the sum of Machine Runtime and Downtime.

-

Performance: Gauges the machine's output efficiency, computed as the difference between Machine Runtime and Idle Time divided by Machine Runtime.

-

Quality: Measures the output quality, determined by the ratio of (Total Box Count - Number of Faults) / Total Box Count.

Overall Equipment Effectiveness (OEE) is derived by multiplying Availability, Performance, and Quality scores, providing a holistic view of machine productivity.

7) Alarm History

This table shows a chronological history of faults or warnings the machine has flagged. Click on the clock icon within the table to modify the historical time window or select between dates. For an in-depth analysis of alarms, see the Alarm Analytics page.

Warehouse Summary

This page offers a comprehensive snapshot of your warehouse performance, showcasing key metrics gathered from all machines.

1) Navigation Bar

Switch between various preset time frames using the center buttons or fine-tune your view by selecting specific dates using the date range selector.

2) Quick Access Tiles

-

Boxes: The total number of boxes sealed by all machines for the given time window

-

Avg Speed: Average machine speed measured in boxes per minute

-

Tape Used: Total amount of tape used by all machines

-

Success Rate: The percentage of boxes effectively sealed relative to the total number of boxes processed

-

Avg Response Time: The average time it took for a fault to be cleared across all machines

-

Active Machines: The number of machines active during the selected timeframe

3) Warehouse Utilization

A chart displaying the percentage of time the machines were in the following states:

-

Idling: Machine is powered on but not actively sealing boxes

-

Active: Machine is actively sealing boxes

-

Faulted: Machine was in the faulted state and stopped

4) Production History

This chart visualizes the cumulative boxes sealed and tape utilized across all machines within the chosen time frame. Please note that tape usage data will be omitted if tape monitoring is disabled for a specific machine.

5) OEE Ranking

A ranking of machine productivity based on Overall Equipment Effectiveness (OEE). OEE is calculated based on three key metrics:

-

Availability: Assesses the machine's utilization rate, calculated as Machine Runtime divided by the sum of Machine Runtime and Downtime.

-

Performance: Gauges the machine's output efficiency, computed as the difference between Machine Runtime and Idle Time divided by Machine Runtime.

-

Quality: Measures the output quality, determined by the ratio of (Total Box Count - Number of Faults) / Total Box Count.

Overall Equipment Effectiveness (OEE) is derived by multiplying Availability, Performance, and Quality scores, providing a holistic view of machine productivity.

Alarm Analytics

This page is designed to provide an in-depth analysis of machine alarms and fault patterns.

1) Navigation Bar

Switch between various preset time frames using the center buttons or fine-tune your view by selecting specific dates using the date range selector.

2) Machines List

A list of all available machines with an active DAS-Cloud subscription. Selecting a machine in the list will load the alarm distribution chart.

-

Boxes: The total number of boxes taped during the selected time window.

-

Success Rate: The percentage of boxes successfully sealed relative to the total processed.

3) Alarm Distribution

A Pareto chart showing the occurrence of each fault and their respective percentage from most frequent to the least. Use this chart to determine which faults are most prevalent and pinpoint how to reduce unplanned downtime.

4) Instantaneous Success Rate

This chart visually tracks the success rate variations of machines over time, highlighting intervals with heightened fault incidents. While the Machines List offers an overall success rate for a set timeframe, the Instantaneous Success Rate chart provides moment-by-moment granularity. A dip in success rate indicates repetitive faults, necessitating prompt intervention for remedial action.

Shift Metrics

1) Navigation Bar

Switch between various preset time frames using the center buttons or fine-tune your view by selecting specific dates using the date range selector. Click on the Shift Schedule button to configure shift tracking.

2) Shift Productivity

Evaluate shift efficiency during the selected time frame through the following metrics:

-

Utilization Chart: Displays the percentage of time the machines were in the following states:

-

Idling: Machine is powered on but not actively sealing boxes

-

Active: Machine is actively sealing boxes

-

Faulted: Machine was in the faulted state and stopped

-

-

Uptime: Total uptime of all machines

-

Boxes: The total number of boxes taped during the shift for the selected time window

-

Faults: The cumulative number of machine faults that occurred during the shift

-

Avg Response Time: The average time it took for a fault to be cleared on a machine

3) Shift OEE

This chart plots shift productivity based on Overall Equipment Effectiveness (OEE). OEE is calculated based on three key metrics:

-

Availability: Assesses the machine's utilization rate, calculated as Machine Runtime divided by the sum of Machine Runtime and Downtime.

-

Performance: Gauges the machine's output efficiency, computed as the difference between Machine Runtime and Idle Time divided by Machine Runtime.

-

Quality: Measures the output quality, determined by the ratio of (Total Box Count - Number of Faults) / Total Box Count.

Overall Equipment Effectiveness (OEE) is derived by multiplying Availability, Performance, and Quality scores, providing a holistic view of machine productivity.

4) Production History by Shift

This chart visualizes the cumulative boxes sealed and tape utilized across all machines by each shift.

Data Forecasting

This page provides a prediction on the amount of time required in the next 3 months. The prediction algorithm used is the Fast Fourier Transform and may not be accurate without sufficient data (several months). Note that for A-series machines, disabling tape monitoring will also disable tape tracking and cause the chart below to be inaccurate.

Maintenance Planner

This page enables you to monitor maintenance intervals for your machine components, ensuring optimal performance. Focus parts on each component are tracked individually based on machine use. When the progress bar approaches 100%, it is time to replace or service the listed part. Once the part has been serviced, click the Completed button to reset tracking and the last service date. After servicing, simply click the "Completed" button to reset the tracking and update the service date. Maintenance reminders are sent within the Weekly Report if enabled.

Comments

0 comments

Article is closed for comments.